|

|

|

|

|

|

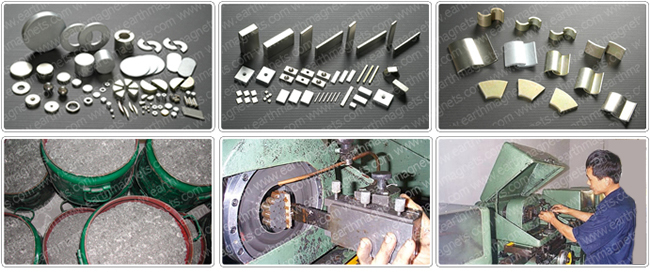

燒結釹鐵硼稀土永磁材料誕生於八十年代初,是當今世界最強的永磁材料。

主要由釹,鐵,硼三種化學粉末混制而成。

主要特點:

具有高剩磁,高矯頑力及高磁能積等優點。

表面通常需作電鍍處理,如鍍鋅,鎳,鎳+銅+鎳,金等,也可以做磷化或

環氧樹脂處理以減慢其氧化速度。以保證産品的耐腐蝕性。

可以通過磨削,線切割,切片,打孔等加工方法生産。 |

| |

|

| |

|

| |

|

Magnetic Characteristics & other physical characteristics of Sinteres NdFeB Magnet Magnetic Characteristics & other physical characteristics of Sinteres NdFeB Magnet

|

|

Grade |

Residual induction

Br |

Intrinsic Coercive

Hcj |

Coercive Force

Hcb |

Max.Energy Product

KJ/m3 |

Tem. Coefficient |

Curie |

Operating |

T

(KGs) |

KA/m

(KOe) |

KA/m

(KOe) |

(BH)max |

(Br) |

|

|

Max |

Min |

Max |

Min |

Max |

Min |

EMN35 |

1.21

12.1 |

1.17

11.7 |

≧955

≧12 |

907

11.4 |

860

10.8 |

279

35 |

263

33 |

=-0.12%/℃ |

310 |

≦80 |

EMN38 |

1.26

12.6 |

1.22

12.2 |

≧955

≧12 |

907

11.4 |

860

10.8 |

303

38 |

287

36 |

=-0.12%/℃ |

310 |

≦80 |

EMN40 |

1.29

12.9 |

1.26

12.6 |

≧955

≧12 |

907

11.4 |

860

10.8 |

318

40 |

303

38 |

=-0.12%/℃ |

310 |

≦80 |

EMN42 |

1.33

13.3 |

1.30

13.0 |

≧955

≧12 |

907

11.4 |

860

10.8 |

334

42 |

318

40 |

=-0.12%/℃ |

310 |

≦80 |

EMN45 |

1.37

13.7 |

1.33

13.3 |

≧955

≧12 |

907

11.4 |

860

10.8 |

358

45 |

342

43 |

=-0.12%/℃ |

310 |

≦80 |

EMN48 |

1.42

14.2 |

1.36

13.6 |

≧955

≧12 |

907

11.4 |

860

10.8 |

382

48 |

358

45 |

=-0.12%/℃ |

310 |

≦80 |

EMN35M |

1.21

12.1 |

1.17

11.7 |

≧1114

≧14 |

907

11.4 |

860

10.8 |

279

35 |

263

33 |

=-0.10%/℃ |

340 |

≦100 |

EMN38M |

1.26

12.6 |

1.22

12.2 |

≧1114

≧14 |

907

11.4 |

860

10.8 |

303

38 |

287

36 |

=-0.10%/℃ |

340 |

≦100 |

EMN40M |

1.29

12.9 |

1.26

12.6 |

≧1114

≧14 |

907

11.4 |

860

10.8 |

318

40 |

303

38 |

=-0.10%/℃ |

340 |

≦100 |

EMN42M |

1.33

13.3 |

1.30

13.0 |

≧1114

≧14 |

907

11.4 |

860

10.8 |

334

42 |

318

40 |

=-0.10%/℃ |

340 |

≦100 |

EMN45M |

1.37

13.7 |

1.33

13.3 |

≧1114

≧14 |

907

11.4 |

860

10.8 |

358

45 |

342

43 |

=-0.10%/℃ |

340 |

≦100 |

EMN30H |

1.12

11.2 |

1.08

10.8 |

≧1353

≧17 |

844

10.6 |

804

10.1 |

239

30 |

223

28 |

=-0.10%/℃ |

340 |

≦120 |

EMN33H |

1.17

11.7 |

1.14

11.4 |

≧1353

≧17 |

844

10.6 |

820

10.3 |

263

33 |

247

31 |

=-0.10%/℃ |

340 |

≦120 |

EMN35H |

1.21

12.1 |

1.17

11.7 |

≧1353

≧17 |

876

11.0 |

860

10.8 |

279

35 |

263

33 |

=-0.10%/℃ |

340 |

≦120 |

EMN38H |

1.26

12.6 |

1.22

12.2 |

≧1353

≧17 |

907

11.4 |

860

10.8 |

303

38 |

287

36 |

=-0.10%/℃ |

340 |

≦120 |

EMN40H |

1.29

12.9 |

1.26

12.6 |

≧1353

≧17 |

907

11.4 |

860

10.8 |

318

40 |

303

38 |

=-0.10%/℃ |

340 |

≦120 |

EMN42H |

1.33

13.3 |

1.30

13.0 |

≧1353

≧17 |

907

11.4 |

860

10.8 |

334

42 |

318

40 |

=-0.10%/℃ |

340 |

≦120 |

EMN30SH |

1.12

11.2 |

1.08

10. |

≧1592

≧20 |

844

876 |

804

10.1 |

239

30 |

223

28 |

=-0.10%/℃ |

340 |

≦150 |

EMN33SH |

1.17

11.7 |

1.14

11.4 |

≧1592

≧20 |

876

11.0 |

820

10.3 |

263

33 |

247

31 |

=-0.10%/℃ |

340 |

≦150 |

EMN35SH |

1.21

12.1 |

1.17

11.7 |

≧1592

≧20 |

907

11.4 |

860

10.8 |

279

35 |

263

33 |

=-0.10%/℃ |

340 |

≦150 |

EMN38SH |

1.26

12.6 |

1.22

12.2 |

≧1592

≧20 |

907

11.4 |

860

10.8 |

303

38 |

287

36 |

=-0.10%/℃ |

340 |

≦150 |

EMN40SH |

1.29

12.9 |

1.26

12.6 |

≧1592

≧20 |

907

11.4 |

860

10.6 |

318

40 |

303

38 |

=-0.10%/℃ |

340 |

≦150 |

EMN28UH |

1.08

10.8 |

1.04

10.4 |

≧1989

≧25 |

812

10.2 |

780

9.8 |

223

28 |

207

26 |

=-0.10%/℃ |

340 |

≦180 |

EMN30UH |

1.12

11.2 |

1.08

10.8 |

≧1989

≧25 |

844

10.6 |

804

10.1 |

239

30 |

223

28 |

=-0.10%/℃ |

340 |

≦180 |

EMN33UH |

1.17

11.7 |

1.14

11.4 |

≧1989

≧25 |

876

11.0 |

820

10.3 |

263

33 |

247

31 |

=-0.10%/℃ |

340 |

≦180 |

EMN35UH |

1.21

12.1 |

1.17

11.7 |

≧1989

≧25 |

907

11.4 |

860

10.8 |

279

35 |

263

33 |

=-0.10%/℃ |

340 |

≦180 |

EMN28EH |

1.08

10.8 |

1.04

10.4 |

≧2387

≧30 |

812

10.2 |

780

9.8 |

223

28 |

207

26 |

=-0.10%/℃ |

340 |

≦200 |

EMN30EH |

1.12

11.2 |

1.08

10.8 |

≧2387

≧30 |

844

10.6 |

8.4

10.1 |

239

30 |

223

28 |

=-0.10%/℃ |

340 |

≦200 |

EMN33EH |

1.17

11.7 |

1.14

11.4 |

≧2387

≧30 |

876

11.0 |

820

10.3 |

263

33 |

247

31 |

=-0.10%/℃ |

340 |

≦200 |

|

| |

|